✕

相关服务可先添加

客服二维码咨询

✕

✕

1.Technical characteristics and parameters

|

Item No. |

Voltage V |

Frequency Hz |

Power Kw |

Current A |

Capacity |

Outer Size mm |

|

JL-NP10 |

220 |

50Hz |

1.5+0.7 |

10 |

10L |

265*410*615 |

|

JL-NP12 |

220V |

50H |

2+0.7 |

12.3 |

12L |

265*410*615 |

2.Machine description

1、PID Temperature

2、Hot Waster knob

3、Hot Water Outlet

4、Water Filter Plate

5、Pressure Gauge

6、Steam Knob

7、Temperature probe

8、Steam Outlet

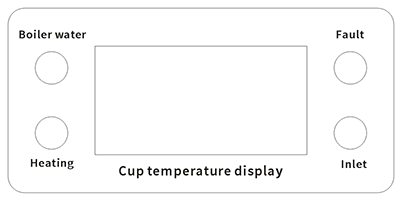

3、Control panel indication

①Boiler water : When tank water is 100℃, the indicator is red.

②Heating: If water is heating , the indicator is green

③Fault: If machine is get some problem, the indicator is red.

④Inlet: Indicator is Green if water is pulling inside:

4、Machine shut down, maintain and clean

①When the machine needs to be turned off, press the power switch to turn off all indicators. Tips: For long periods of downtime, it is recommended to unplug the machine for safety reasons

②Machine Maintenance

If the above operations are performed, basically no other maintenance measures are required.

When repairing/replacing an accessory that comes into contact with food or water, a cleaning process must be performed or the manufacturer’s instructions must be performed.

③Machine cleaning

The following tale must be cleaned with the machine turned off, the power turned off , and cooled to room temperature.

The cleaning frequency is shown in the following table:

|

Cleaning Unit |

Cleaning Frequency |

|||

|

Name |

After use |

Every day |

Every week |

|

|

1 |

Steam Nozzle |

√ |

√ |

√ |

|

2 |

Water filter plate |

|

√ |

√ |

|

3 |

Machine cover |

|

√ |

√ |

|

4 |

Hot water outlet |

|

√ |

√ |

5、Problem solving table

①Mechanical equipment may cause mechanical failure due to operational errors, aging of accessories, etc., resulting in the machine not being able to operate normally. Therefore, the manufacturer’s long-term summary of maintenance/repair experience is compiled into a table. To reduce the user because of simple mechanical failure and wait for maintenance time and related costs. (wearing parts and rubber rings are not covered by the warranty. When the mail power cord is damaged. It must be replaced by a professional.)

② If the machine is not working properly, please check the problem according to the following fault table.

|

Trouble |

Solutions |

|

Do not output hot water |

The machine is not heated or has no steam pressure The out put port is blocked or teh valve body is blocked |

|

No steam output |

Steam nozzle blockage The water level is too high, open the hot water or drain. Insufficient boiler pressure or no heating |

|

Boiler is full of water |

The water inlet solenoid valve is not tight or blocked. It is necessary to disassemble the valve body to clean or contact the technician for aging |

|

Air leaking from the vacuum breaker valve |

The gasket is worn out Valve pin to the middle |

|

Safety valve leak |

The spring is weak and the safety valve needs to be replaced |

|

Not Heated |

Temperature probe failure Overheat protector failure |

|

Steam nozzle or hot water port drip |

The gasket is worn out |

这不是本机号码?请修改 >

为保证服务质量,你的通话可能会被录音

为保证服务质量,你的通话可能会被录音

呼叫失败您可以尝试拨打